A very sobering thought and a reminder of the dangers at work.

Complacency is often the tipping point, and once things go wrong, changes around the site tend to ensue. A quick look at other sites can highlight what you can do to keep your employees safe.

Let’s take a look at 8 things your competitors can teach you about field and forklift safety in your facility.

1. Speed limit:

This sounds logical, but you’d be surprised to know that some sites don’t display forklift speed limits within their stations, although you may reiterate to staff dangerous and acceptable speeds – reminders in the form of signage can only help point out Indicates that a speed limit exists and is enforced by management in much the same way that road speed limits are enforced (without a flashing blue light behind you, but in the form of a “raised eyebrow” boss). Speed limits in different areas of a factory are critical to forklift safety. It also enables more efficient estimation and calculation of logistics costs; ensuring a better understanding of traffic movements.

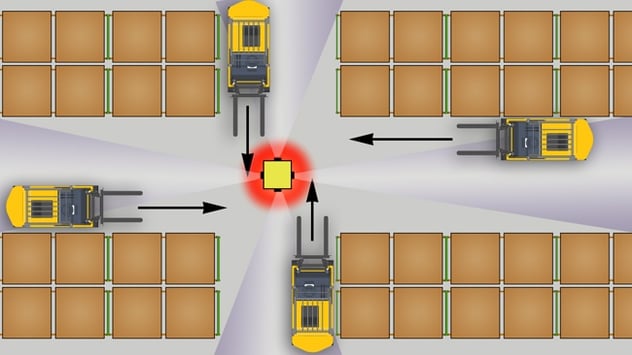

2. Visibility:

A common factor that goes hand in hand with warehouses and industrial areas is…noise (sorry, what did you just say?). Noise from machinery, welding, vehicles, tools, etc. On top of everyday noise, factory workers may also wear headphones or headphones/earmuffs to protect their ears from heavy machinery noise, or just listen to the radio while working. The operating noise of a forklift may seem to be enough to warn others that it is oncoming, but in reality, the noise of a forklift can easily be drowned out by other day-to-day activities. Don’t rely on noise to warn employees/employees/pedestrians of forklift traffic. Visibility of potentially hazardous machinery should be carefully considered.

Consider the very clever LED integrated traffic lights available on some high speed fast rollers

To reduce risk and improve workplace safety, increased visibility across the workplace is critical.

3. Maintenance and maintenance:

Maintain and stick to maintenance schedules and prioritized machine maintenance as much as possible. This applies not only to machines, but also to software and products – with each new upgrade or release; products and software are often improved and given the opportunity to address previous security issues and concerns. It is often not possible to have the best of all versions on site, but safety features and investments in new products and machines often far outweigh the financial and emotional costs of accidents at work.

Maintenance solutions for items such as high-speed doors and forklifts help reduce equipment damage and wear and tear caused by operator error. This in turn will reduce maintenance and damage repair costs; such as tire and tying wear; general body damage; hydraulic damage and other essential equipment damage.

4. Traffic Management Plan

It’s never too late to review and/or change your traffic management plan. As the years go by, companies grow/expand/change/shrink (whatever that is) and evolve, no matter how annoying the problem is – or how easy it is to change.

We all do this at home too – how often do you put up with something that really annoys you – maybe a dripping faucet / ripped or torn floor or carpet / squeaky door or handle when you finally When you took the time to deal with it, when it was fixed, did you wonder why it took so long?

When a problem becomes “the norm,” they are easily forgotten. Taking a close look at your traffic management plan and considering any small changes can increase your efficiency and save a lot of hassle.

Work Safe health and safety general manager Lisa Sturzenegger said forklifts were the leading cause of workplace death and serious injury in Victoria.

“Forklifts and people working nearby simply don’t mix. A traffic management plan that physically separates forklifts and people is critical,” she said.

For more information on forklift safety visit worksafe.vic.gov.au

5. Complacency:

A typical example we ran into recently was a recent update to a general manual, in the last draft of the manual, after weeks of revisions/changes, the day before it was approved for printing, an electrician mentioned that the wiring diagram was incorrect – – All previous versions were buggy, the live team knew about it and fixed it, but never asked management to change it.

Never assume it’s the right thing to do just because everyone else is doing it wrong.

6. Transcript

We cannot stress enough the importance of written proof/paperwork/written records when implementing security systems at work. Word of mouth is not enough. In the tragedy of a worker involved in a forklift truck accident in 2012 – a trucking company was convicted and killed after a worker was thrown from a forklift truck and crushed to death by a computer server weighing 635kg at its Laverton North warehouse. Fined $375,000 to die.

The court heard the company had failed to enforce the no-go zone as the oversized cargo was being unloaded from the truck. While it has a safety policy requiring all employees to stay at least two meters away from working forklifts, the company has no written record that the man was informed of the requirement.

Always stay safe and post safety notices to every employee – ask them to read and sign and keep it in your records

Seven, restricted area

In a way – this goes hand in hand with your traffic management plan. Installing guardrails, bollards and barriers around certain restricted areas of your site can be quite cheap, and we often don’t think much of it until it happens. Especially if your employees have been working with you for years – it’s easy to assume everyone knows the danger zone. Remember this – it’s cheaper for you to protect than to fix! A small accident can result in huge repair bills.

8. Signage

Clear and appropriate on-site signage to guide and assist customers/employees/visitors. Put yourself in the shoes of a first-time visitor to your website. Will they know where to find finance/administration/first aid kit/toilet?

Sometimes you can improve site security by simply increasing the speed at which you can find information and help.