News

Forklift Truck Operator Pre-Use Checks

Forklifts are extremely useful workplace vehicles, as long as they are used safely and appropriately by operators who are appropriately trained and competent to use them. The following forklift safety tips will help you and those you work with stay safe around forklifts. Check Items Visual Checks 1 General: Good

Significance of Smart Sensors for Industry 4.0

In smart manufacturing facilities, smart sensors provide the opportunity to determine failure, increase efficiency, and monitor levels to design a smart factory. The sensors are vital components of Industry 4.0, allowing several transitions such as changes in positions, lengths, heights, external pressures, and dislocations to be measured, analyzed, and processed.

How To Choose A Forklift That Suits You

Forklift is suitable for all industries, but it is very difficult to buy a suitable forklift truck. Such as electric forklift or internal combustion forklift, or even choose a small electric forklift, such as electric stacker, electric pallet? These are puzzles! So how to choose more suitable forklift for us?

Spring Forklift Maintenance Tips

The spring of new year, with the temperature rise and the progress of the project started, forklifts will be a heavy load period after experiencing the winter. In this period, it is necessary to check and maintenance forklifts. Body paint It is necessary to clean the body regularly after a

Why are there so many fuel options for forklifts? Electric, Petrol, LPG, Diesel

Forklift’s feature a variety of different options; fuel type, capacity, lift height, mast options and the list goes on. The important thing to remember when you are in the market to purchase a forklift – there are experienced consultants who can help you make the best decision based on your

3 Industries Made More Efficient by the Forklift

Like most products, the forklift was born out of necessity. In this case, it was to move heavy materials short distances. In the early part of the 20th century, the forerunners to the modern forklift were powered hoists that were used to lift loads. World War I increased the need

Steps You Can Take To Reduce Forklift Damage

There is a reason someone must be certified before operating a forklift. These heavy pieces of machinery are capable of doing a lot of work – or a lot of damage. When operated incorrectly, products and materials can be broken or damaged, costing companies extra time and money. Fortunately, there

How can you work safely with a pipe rail trolley?

Pipe rail trolleys are used regularly for carrying out work at height in greenhouse horticulture, particularly in harvesting and crop care. However, working with a pipe rail trolley does involve risks. That is why it is very important that those who work at height are aware of the safety measures, so

4 REASONS TO PURCHASE AN ELECTRIC PALLET JACK

Reduce investment costs and injuries with an electric pallet jack for your warehouse. The material handling industry categorizes forklifts into various classes. The Class III product includes a variety of electric motor forklifts that are either walk-behind or standing-rider operated, such as the electric pallet jack. Regardless of the

How Does a Walkie Stacker Work?

How Does a Walkie Stacker Work? Walkie stackers can be manual or powered. And how they are operated varies accordingly. To use a manual walkie stacker, an operator must push the machine on their own. The stacker has a foot pedal or handle, so an operator can raise its

HOW TO CHOOSE A MANUAL PALLET JACK

There are a few key reasons why someone might purchase a manual pallet jack. Perhaps the most common reason is that a business needs to move pallets of goods around and there is no motorized pallet jack available, or it is not practical to use one. Other reasons might include

How to Operate an Electric Pallet Jack

Electric pallet jacks can be even more convenient to use than manual pallet jacks, as the manual motion of jacking up the prongs is done electronically. Many also have a “ride-on” feature that can make it easier to get around a large warehouse. Unplug and Store Cord Unplug the electric

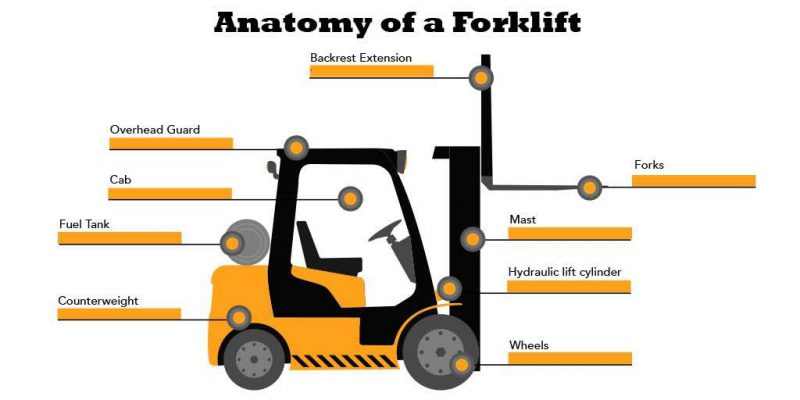

Anatomy of a Forklift Truck

Cab The cab is where the operator sits or stands and contains the controls for operating for the forklift. The controls include the steering wheel, lift controls, brake and accelerator pedals, safety signals, and more. Overhead Guard Directly above the cab is the overhead guard. This protects the forklift operator

Gas vs. Electric Forklift: Which Should I Choose?

There was a time when there wasn’t even a question about which type of forklift you should choose to use in your warehouse or facility. Gas-powered forklifts were the go-to for every business needing help moving materials around the job site. Then electric-powered forklifts became available, and these new machines offered

Warehouse Forklifts: Which Lift Truck is Best?

Do you have a warehouse in need of forklift help? There are several different forklift types, or classifications, depending on the specific needs of the business. If you’re looking for the best warehouse forklift for your business, The Forklift Pro has a few tips to help. Warehouse Fork Lift Classifications There are

The Power Behind the Lift: Proper Forklift Battery Care

Here at Sinolift, our maintenance checks on new and used equipment don’t stop with the moving parts. Every piece of equipment is thoroughly checked before reaching your facility. What’s under the hood is just as important, and we take extra care to ensure that the battery in your forklift is

Sit Down Versus Stand Up Forklifts

Though the end goal for all forklift types is to safely and efficiently move product, each forklift type varies greatly. Determining the best forklift for your application is not only going to save you time and money, but the decision will also benefit your operations from a safety standpoint. Counterbalanced

What not to do on a Forklift

When it comes to forklift operation, safety should always be number one. Operating material handling equipment, especially in places like warehouses, comes with a lot of responsibility. Sometimes you can become too comfortable in the day-to-day action and activity, and forget how to practice forklift safety. The Forklift Pro is

Forklift Attachments Series: Where Would We be Without the Side Shift?

Forklifts have come a long way since the first efforts combining horizontal and vertical movement staring back in 1887. Even with all the advancements in technology from a safety and productivity standpoint, there are still more ways to save time, money, and increase worker safety when it comes efficiently running

Small Forklifts: When Size Matters

It may seem as though owning a forklift is impossible due to the tight quarters of your warehouse, but sinolift is here to change that thought. Small forklifts are the key to the increased efficiency and productivity that you need. Best Type of Lift Truck for Tight Spaces For small

WHY IS OVERLOADING A FORKLIFT DANGEROUS?

1,500 injuries are caused by forklifts and other industrial vehicles every year. Whilst unavoidable accidents can happen, many accidents can occur by misoperation or negligence of a forklift truck, which could easily be avoided if educated correctly. Overloading a forklift truck is a key example of negligence which can cause

WHAT ARE THE DIFFERENT TYPES OF FORKLIFTS, AND WHAT ARE THEY MOST SUITED TO?

WHAT ARE THE DIFFERENT TYPES OF FORKLIFTS, AND WHAT ARE THEY MOST SUITED TO? Forklifts are necessary in helping to carry out lifting and transportation tasks, where objects are too heavy to rely on just human strength alone. Whether you want to purchase a forklift for use in a warehouse

COMMON FORKLIFT PROBLEMS AND HOW TO FIX THEM

Whether you’re a seasoned forklift operator or just starting out with your training, you’ll know that forklift trucks often develop faults despite regular maintenance by a professional. To help you spot any potential issues early, here’s a list of the most common forklift problems and how to fix them. The

Forklift Maintenance 101 Benefits, Frequency and Cost

Forklifts require full maintenance and servicing every 200-250 hours of operation or every six weeks. Before using a forklift on any job site, it should undergo a daily inspection. Not only does forklift maintenance keep your machine in top condition, but it also helps you avoid safety hazards. Forklift maintenance