Pallet jacks are versatile tools used to transport pallets and other small loads over short distances. They are common in stores and warehouses, and their size makes them suitable for personal and commercial use.

Because they come in multiple sizes and styles, it’s important to understand the differences between different types of pallet jacks before renting or purchasing a new one. If you’re looking to add a new pallet jack to your workspace, read on for an overview of the different types.

Manual Pallet Jacks

Manual pallet jacks work by operating a lever attached to a hydraulic pump. They are the simplest version of a forklift available, and their size makes them easy to transport and maneuver through tight spaces.

The manual version has a lower weight limit than most electric models and requires more manual labor to operate. However, it is typically more affordable and requires less maintenance, making it a popular option for smaller warehouses and outdoor worksites.

While most manual pallet jacks operate in the same way, there are a few different types to look out for. Read through the following manual options to learn which model is best suited for your specific warehouse or worksite.

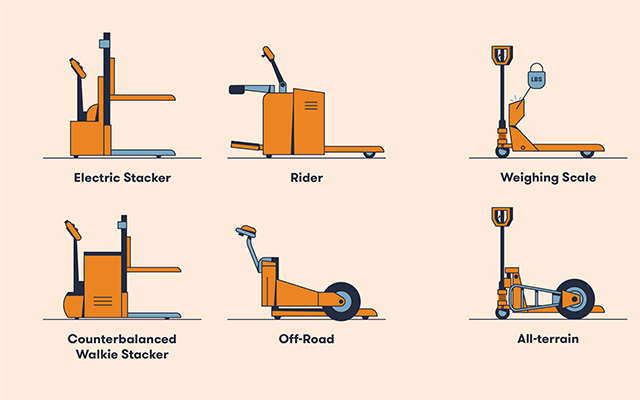

1. Weighing Scale

Weighing scale pallet jacks are equipped with a digital scale that displays the weight of each load. This is advantageous if you regularly need to check weights in a loading bay or factory setting. The scale itself is battery-operated, and some have a printer attachment that allows you to print out the weight reading or other information.

Best suited for: Loading bays, factories

2. Adjustable

The forks on the adjustable model can be readjusted to accommodate wider or narrower loads. This model is ideal for those who work with different-sized pallets. Other manual jacks also come in wide or narrow options, but the adjustable version is more versatile and cuts down on storage space.

Best suited for: Workspaces with pallets of varying sizes

3. All-Terrain

All-terrain pallet jacks come with larger wheels designed to handle rough and uneven surfaces. Their strong, lightweight frame makes them easy to maneuver, and their wheels are wide-set to help prevent the load from tipping or sliding. They are more difficult to maneuver in tight spaces, but their shock-absorbing outriggers make them perfect for uneven floors and outdoor projects.

Best suited for: Outdoor worksites or uneven floors

4. Mini

Mini pallet jacks are easier to maneuver and are designed to lift smaller loads. They are ideal for tight turns and smaller isles, and their lightweight frame makes them easy to store and transport. They also lack a hydraulic pump, making them less costly to maintain than other types of manual pallet jacks.

Best suited for: Light loads, small workspaces

Electric Pallet Jacks

Electric pallet jacks serve the same function as their manual counterparts but operate a bit differently. Rather than requiring a hydraulic pump to operate, the prongs of an electric pallet jack raise and lower electronically and are controlled by buttons or levers.

As the name suggests, electric pallet jacks are powered by a rechargeable battery that must be plugged in between uses. This can be inconvenient if you don’t have easy access to a charging station, but the battery saves on manual labor and increases overall efficiency.

Electric jacks are more expensive than manual models and require more training to operate, but they are worth it if you have a large warehouse or need to transport pallets over longer distances. If you’re looking to buy or rent the electric version, below are some of the most common types to consider.

5. Electric Walkie Stacker

The electric walkie stacker is a battery-operated pallet jack that requires the operator to walk behind or alongside it as it moves. It is significantly larger than a manual pallet jack, and its lifting capacity typically ranges from 4,500 to 6,000 pounds, making it well-suited for heavier loads.

The electric walkie pallet stacker is still small enough to maneuver through tighter spaces, but its larger size can make it difficult to transport.

Best suited for: Mid-distance projects, standard warehouses

6. Rider

The rider pallet jack comes with a riding platform for the operator to stand on. This version is similar to the electric walkie behind in that it is powered by a rechargeable battery and has similar controls. However, it is much bigger and heavier, making it better suited for large warehouses and longer distances.

If you are interested in buying or renting this type of pallet jack, be sure to carefully read through the safety and operating instructions before use.

Best suited for: Large warehouses, heavy loads

7. Counterbalanced Walkie Stacker

If you need to store pallets in high areas beyond a traditional pallet jack’s reach, the counterbalanced walkie stacker could be the best option for you. It comes with a heavy lifting mast and uses the back end as a counterweight to prevent it from tipping over, making it better equipped to lift heavy loads high above the ground. However, its longer body prevents it from making tight turns in small, cramped spaces.

Best suited for: General warehouses, high storage spaces

8. Off-Road Electric

Similar to the all-terrain manual model, the off-road electric pallet jack is designed to operate on rough or uneven surfaces. It comes with durable tires and a wider frame and is powered by a rechargeable battery. The off-road electric pallet jack is perfect for transporting heavy loads across warehouses or outdoor construction sites, and its electric components make it easier to operate than the all-terrain pallet jack.

Best suited for: Uneven floors, construction sites